Adherex packaging | Film

Vented Stretch Film and Netting

Vented Stretch Film

Stretchtape offers multiple vented stretch film and netting options for packages requiring airflow and temperature regulation.

Stretchtape’s vented stretch film has die-cut holes through the film, increasing airflow, preventing condensation, and allowing the temperature of the package to be more easily regulated. These properties make vented film ideal for cold and frozen products, including food, produce, and pharmaceutical products.

Vented films can also be used in cases in which moisture may be present while wrapping and could potentially damage the load. For example, vented stretch film is often used for bundling firewood to allow moisture to escape and air to flow rather than collecting mold and potentially damaging the product.

Vented Extended Core Stretch Film

Vented film is available in hand film and machine film. It is applied easily just as any traditional stretch film. It also sticks only to itself, eliminating any worries about residue left on products after removal. Vented stretch film is also designed to be used with traditional wrapping machines, so there is no specialized equipment needed.

These die-cut stretch films provide better load containment than netting and can be used manually and with a machine stretch wrapper.

Vented Machine Film

Features

- Used with traditional wrapping equipment

- Moisture-releasing vents

- Useful for packaging in fluctuating temperatures

Benefits

- Prevents moisture/condensation build up

- Increases air flow

Netting

Stretchtape’s netting offers a lightweight packaging solution for automated and semi-automated food product packaging systems.

The polyethylene or polypropylene netting allows for high visibility of the product and is approved for direct food contact. Unlike cotton or knitted netting, polyethylene or polypropylene netting does not fray when it is cut. In addition to food and produce packaging, netting is also used for medical and pharmaceutical purposes in which products need increased ventilation and flexible packaging.

Features

- Strong knit netting provides excellent load-stability

- Recommended for food industry

- Designed for ventilation

Benefits

- Prevents moisture/condensation build up

- Flexible packaging for loose products

Additional sizes and gauges may be available upon request.

Length: 1000′

Core ID: 1″ extended

Rolls/Case: 4

Length: 2000′

Core ID: 3″

Rolls/Case: 4

Length: 1000′

Core ID: 3″

Rolls/Case: 4

Length: 1000′

Core ID: 1″ extended

Rolls/Case: 4

Length: 3300′

Core ID: 3″

Rolls/Case: bulk

RELATED ARTICLE

Stretch Film Expiration: The Importance of Rotating Stock

Stretch film is essential to transporting and storing goods safely. It keeps items from moving during transit, while protecting products from both indoor and outdoor elements. Due to the product’s importance, companies need to understand how to prevent and detect stretch film expiration. The various film types react differently to extreme heat, cold, humidity, and other factors.

Access to a Broader, More Comprehensive Line of Products

In-Stock, Ready-to-Ship.

Hand- and Machine-Rolled Adhesion Solutions.

Available in Multiple Widths, Lengths & Materials.

Customizable to Meet Exact Customer Specifications.

BOPP Carton Sealing Tapes

BOPP Carton Sealing Tapes

Available in multiple grades of acrylic adhesive, synthetic rubber hot melt, solvent natural rubbers and solvent acrylic adhesives. We’ll meet your application requirements from functional to performance-grade adhesive systems.

Paper Tapes

Paper Tapes

Multiple product grades are available from general purpose tapes to high-performance products. Sizes range from standard market sizes to customized sizes to meet application-specific requirements for splicing, clean removal, UV resistance and more.

Cloth, Duct, Film & Foam

Cloth, Duct, Film & Foam

Single- and double-sided tapes are available in a broad range of grades, colors and sizes on a variety of substrates and specially formulated pressure sensitive adhesives. Performance characteristics range from waterproofing to noise and heat reduction.

Stretch Film

Stretch Film

Strapping Tape

Strapping Tape

Our line of adhesive solutions offers tensile strengths between 70 and 500 pounds to meet each customer’s unique requirements. A broad range of applications include securing products during transfer, carton sealing, bundling, load unitizing, reinforcement and security.

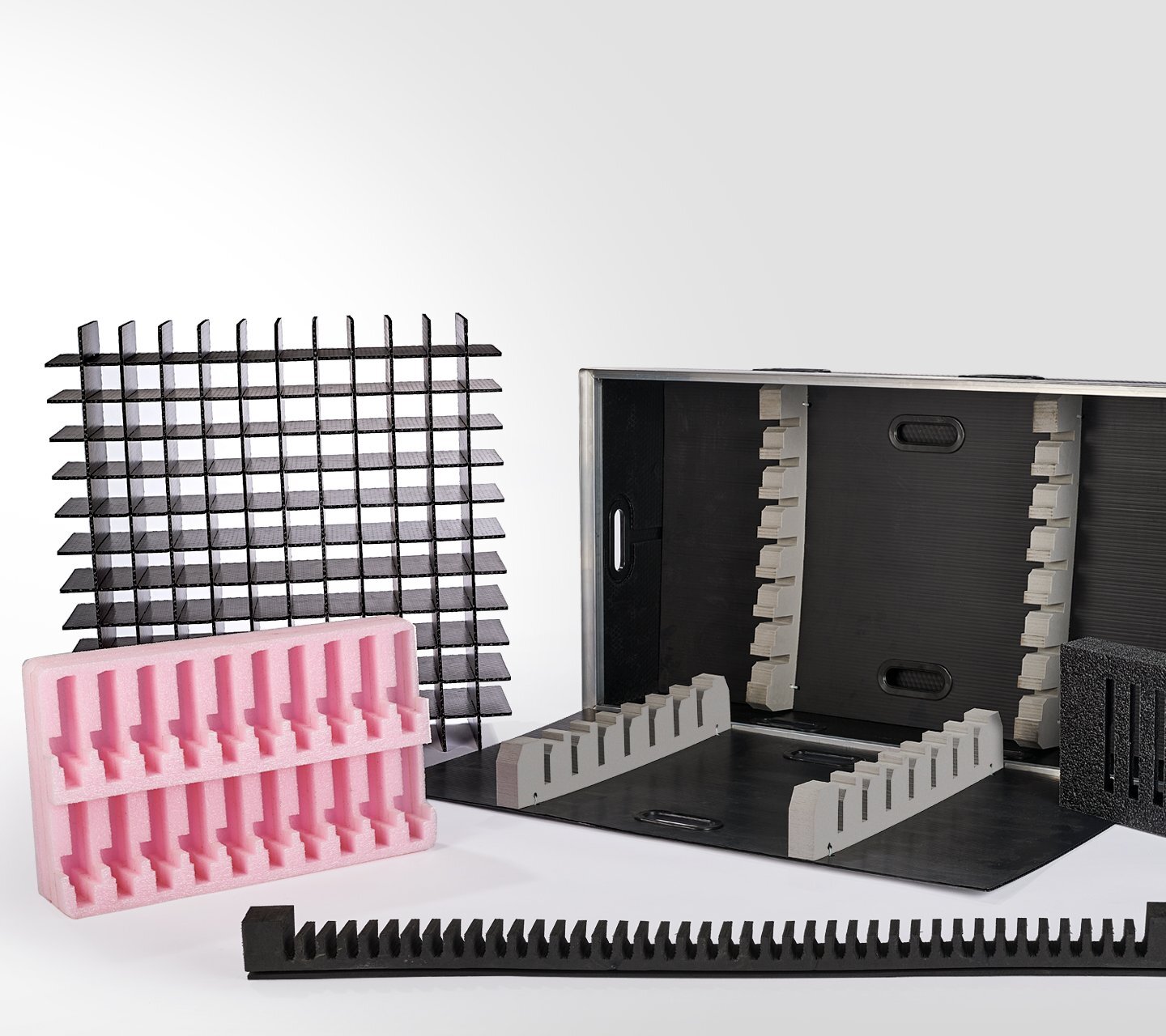

Customized Solutions

Customized Solutions

A wide range of assemblies and kits – including Returnable Packaging and Customized Put-Ups – leverage our in-house die-cutting and converting technologies. We’ll create the durability and strength needed for multiple uses, Class A surface protection and more.

Printable & Printed Tapes

Printable & Printed Tapes

Discover how our BOPP acrylic and hot melt tapes are being used for both top-side, printable products, as well as undersurface/lock printed materials to build awareness for your brand, create pilfer-proof packaging and more.

sanstrap® Pallet Bands

sanstrap® Pallet Bands

Our industry-leading pallet banding solution secures the top layer of a pallet with materials that are both recyclable and durable. The product provides a proven, quick, and easy way to ensure stabilization for intra-plant movement. Its ease of use provides tremendous savings in both labor and time.

Highest Quality Flexographic Film Printing

Highest Quality Flexographic Film Printing

Our advanced eight-color flexographic film printing is available for films up to 41 inches wide. With one of the world’s most productive flexographic printing systems, we can reliably print on multiple substrates including stretch film, low- and high-density PE, BOPP and multilayered film composites. Integrated technologies ensure waste-minimizing set-ups, quick job changes, and automated print monitoring and inspection processes.