Adherex packaging | Tapes

Sound Deadening Tapes

Sound Deadening Tapes

Noise and friction are ever-present hurdles in the manufacturing and automotive industries. Sound deadening tapes dampen packaging noise, seal car interiors, and provide a low-friction surface while offering the same bonding strength as traditional tapes. UHMW tapes are sound deadening adhesive tapes used for package protection and binding in the automotive fields. They glide effortlessly on rough surfaces without damage and retain strength when exposed to harsh chemicals. Flock tape is a fiber-coated tape most often used in car interiors—where its fiber-covered surface deadens road noise and prevents car components from rattling against each other. Flock tape is also used as a protective lining for car windows and jewelry boxes.

UHMW Tape

Flock Tape

Sound Deadening Tape: Quiet and Strong

Strong adhesive tapes seal well but can be inflexible, making them less suitable for high-movement, high-friction applications such as shipping or automotive construction. During transport, rough package surfaces can damage the seals on neighboring packages. High-friction surfaces like conveyor belts and rails can also catch packaging, causing damage.

In the automotive industry, traditional tapes are not flexible enough to stretch with moving pieces, tearing and causing excess noise. Sound deadening UHMW and flock tapes are flexible, durable, and low-friction tapes that resist tearing and reduce noises associated with rubbing and vibration. These tapes provide the adhesion strength needed for demanding industrial jobs while gliding over surfaces and minimizing abrasion.

UHMW Tape vs. Flock Tape

UHMW Tape:

- Low-friction polyethylene tape adheres strongly and creates a slick surface.

- Used in cars to reduce rattle and vibration noise between components.

- Moves silently with the car while also maintaining a firm hold.

- Commonly used in shipping to reduce friction on guard rails and conveyor belts, preventing product damage during transport.

- Highly chemical resistant and can withstand extreme temperatures.

- Versatile and durable low-noise option due to strength and sound deadening properties.

Flock Tape:

- Fiber-lined adhesive tape commonly used in the automotive industry.

- Fibers attach to a plastic adhesive tape, acting as a buffer between a car’s metal, plastic, and glass components to minimize rattling and vibrations during movement and lower the overall noise in the car’s interior.

- Can be applied to metal parts in the dashboard, center console, and even the seat belt clip for noise reduction and protection.

- Used in jewelry boxes and car dashboard displays for its velvet finish.

Why Adherex?

Adherex’s commitment to quality is found in more than just the strength of our tapes. Adherex’s sound deadening UHMW and flocking tapes withstand the toughest industrial demands to minimize squeaking, rattling, and vibrations in a variety of applications.

UHMW tape creates a low-friction surface that resists chemical corrosion and extreme temperatures on car parts, industrial rails, and ramps.

Flock tape shields car interiors from damage and noise, creating a comfortable environment for owners, and is also a reliable aesthetic option for everything from vehicles to jewelry boxes.

Whatever your use case, Adherex’s specialists will help you find the best sound deadening tape option for a professional look, a noiseless space, and protection from wear and tear.

FAQs

Are sound deadening tapes as strong as traditional tapes?

UHMW sound deadening tapes hold as strong as traditional adhesive tapes while offering a low-friction surface.

What is flock tape and what is it used for?

Flock tape is a fiber-lined tape used to control rattling and vibrations in car interiors, and to provide an attractive, velvety finish in certain applications.

Are UHMW tapes effective in harsh conditions?

UHMW tapes are resistant to harsh chemical exposure and extreme temperatures.

RELATED ARTICLE

Understanding the Shelf Life of Adhesive Tapes in Industrial Settings

Understanding the shelf life of adhesive tapes requires some consideration and management on the part of distributors, shippers, and manufacturers. Industrial buyers may purchase dozens or even hundreds of rolls of tape at once and must think about how to best manage shelf life. Custom tapes and other specialty packaging products can have long lead times due to the manufacturing process, which further complicates the shelf life of adhesive tapes.

Access to a Broader, More Comprehensive Line of Products

In-Stock, Ready-to-Ship.

Hand- and Machine-Rolled Adhesion Solutions.

Available in Multiple Widths, Lengths & Materials.

Customizable to Meet Exact Customer Specifications.

BOPP Carton Sealing Tapes

BOPP Carton Sealing Tapes

Available in multiple grades of acrylic adhesive, synthetic rubber hot melt, solvent natural rubbers and solvent acrylic adhesives. We’ll meet your application requirements from functional to performance-grade adhesive systems.

Paper Tapes

Paper Tapes

Multiple product grades are available from general purpose tapes to high-performance products. Sizes range from standard market sizes to customized sizes to meet application-specific requirements for splicing, clean removal, UV resistance and more.

Cloth, Duct, Film & Foam

Cloth, Duct, Film & Foam

Single- and double-sided tapes are available in a broad range of grades, colors and sizes on a variety of substrates and specially formulated pressure sensitive adhesives. Performance characteristics range from waterproofing to noise and heat reduction.

Stretch Film

Stretch Film

Strapping Tape

Strapping Tape

Our line of adhesive solutions offers tensile strengths between 70 and 500 pounds to meet each customer’s unique requirements. A broad range of applications include securing products during transfer, carton sealing, bundling, load unitizing, reinforcement and security.

Customized Solutions

Customized Solutions

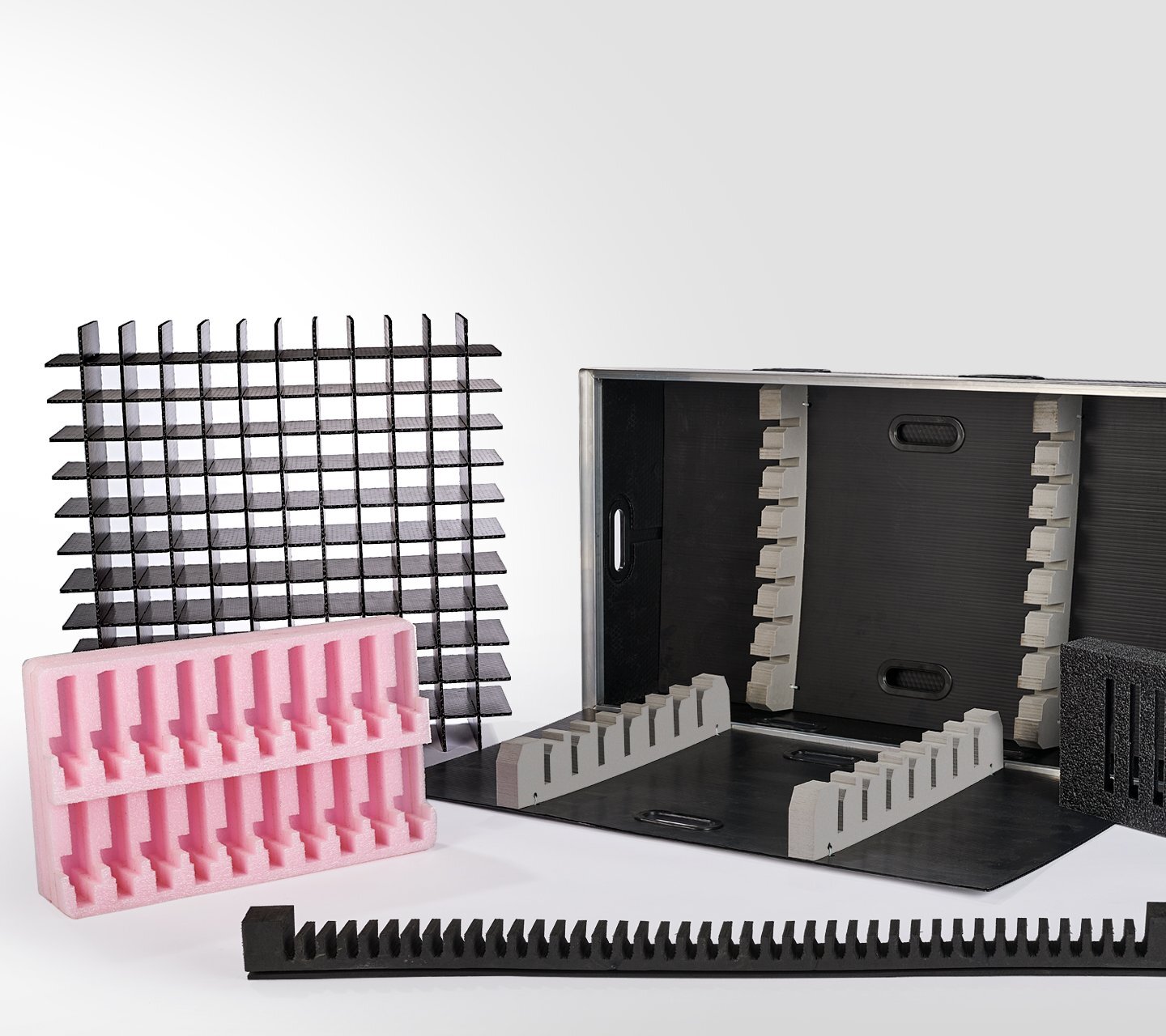

A wide range of assemblies and kits – including Returnable Packaging and Customized Put-Ups – leverage our in-house die-cutting and converting technologies. We’ll create the durability and strength needed for multiple uses, Class A surface protection and more.

Printable & Printed Tapes

Printable & Printed Tapes

Discover how our BOPP acrylic and hot melt tapes are being used for both top-side, printable products, as well as undersurface/lock printed materials to build awareness for your brand, create pilfer-proof packaging and more.

sanstrap® Pallet Bands

sanstrap® Pallet Bands

Our industry-leading pallet banding solution secures the top layer of a pallet with materials that are both recyclable and durable. The product provides a proven, quick, and easy way to ensure stabilization for intra-plant movement. Its ease of use provides tremendous savings in both labor and time.

Highest Quality Flexographic Film Printing

Highest Quality Flexographic Film Printing

Our advanced eight-color flexographic film printing is available for films up to 41 inches wide. With one of the world’s most productive flexographic printing systems, we can reliably print on multiple substrates including stretch film, low- and high-density PE, BOPP and multilayered film composites. Integrated technologies ensure waste-minimizing set-ups, quick job changes, and automated print monitoring and inspection processes.