Adherex packaging | Protective Packaging

Gaskets

Gaskets

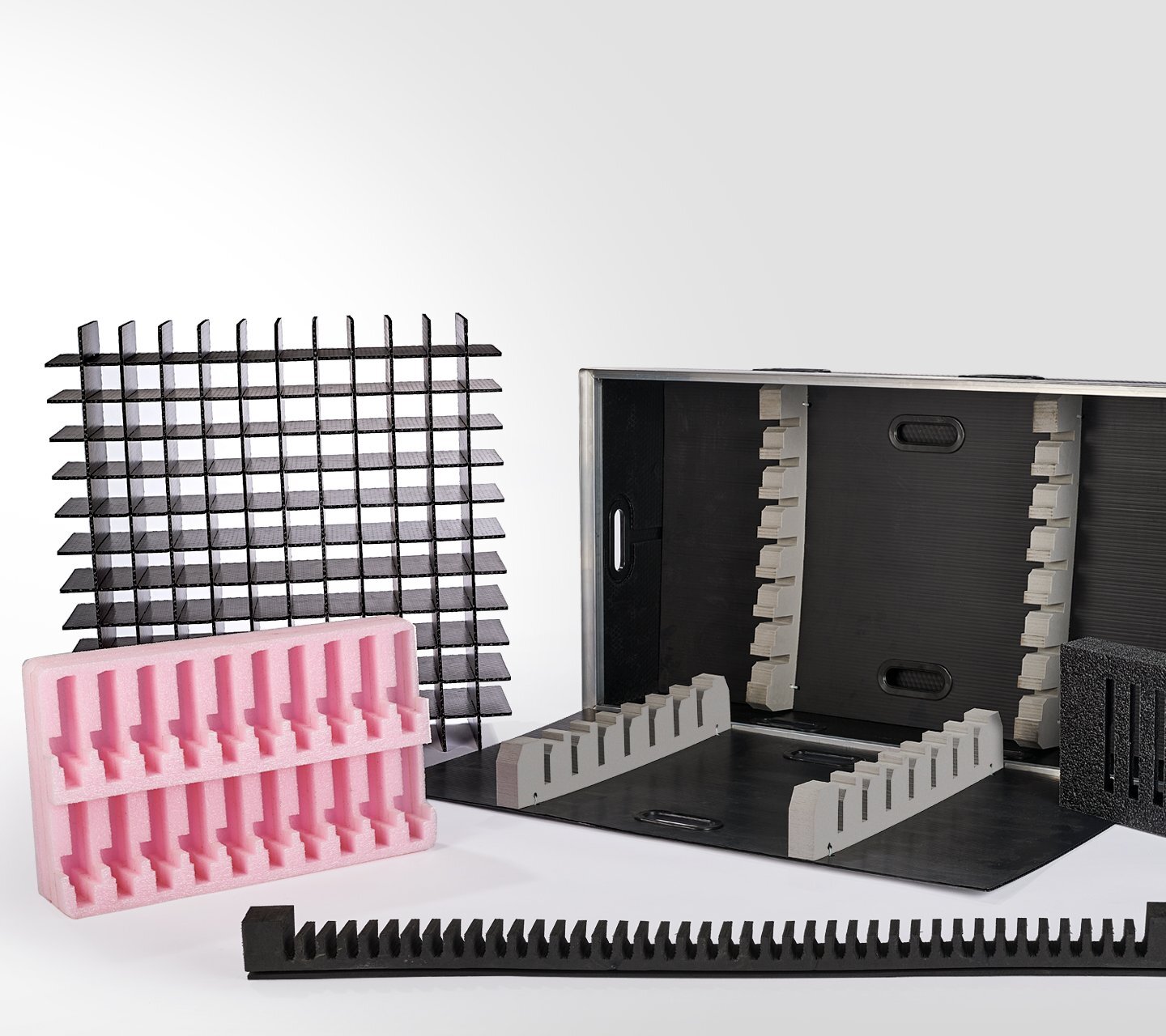

Gaskets serve as essential protective components, designed to seal multiple elements against liquids and gasses while cushioning parts susceptible to damage from movement. These versatile products can be crafted from various materials, each selected for its unique sealing capabilities, structural durability, vibration absorption, and resistance to environmental factors. Gaskets cater to different needs and are available in both open-cell and closed-cell configurations. The open-cell variety provides superior sealing and is more robust, whereas the closed-cell category is not as effective in sealing but excels in offering enhanced cushioning and vibration reduction.

Adherex specializes in die cutting services, providing custom gasket solutions tailored to specific application requirements.

Neoprene Gaskets

Poron Gaskets

Rubber Gaskets

Foam Gaskets

Cork Gaskets

Finding the Right Sealing Solutions

Achieving a reliable seal presents significant challenges in HVAC, automotive, aerospace, plumbing, and industrial applications. These sealing tasks occur in harsh environments subjected to abrasive chemicals, extreme temperatures, and intense pressures, complicating their effectiveness.

Additionally, static electricity accumulation poses a real threat to sensitive electronics. This complexity is compounded by the difficulty of sourcing materials and designs that precisely meet the unique demands of each specific application, highlighting the intricate balance required to ensure durability and functionality.

Adherex helps you determine and source the ideal material and product for your application. We can also create custom die-cut products to fit your exact specifications.

Gaskets for Your Precise Needs

Neoprene gaskets:

- Crafted from neoprene rubber with a closed-cell structure

- Designed to withstand high PSI and extreme temperatures

- Ideal for industrial sealing, general-use sealing, and cushioning applications

- Seals gas and liquid

Poron gaskets:

- Crafted from polyurethane with an open-cell structure

- Anti-static, boasting a high-density composition, enhancing their sealing and cushioning capabilities

- Ideal for electronics due to structural integrity

Rubber gaskets:

- Known for their range of applications

- Essential in cushioning and sealing against gas, oil, water, and more

- Can be cut using materials like nitrile or neoprene to boost heat and pressure resistance

Foam gaskets:

- Crafted from various durable, closed-cell polymers

- Benefits include cushioning, waterproofing, and vibration dampening

- Valuable in car manufacturing

Cork gaskets:

- Crafted by blending ground cork with binders such as glue, rubber, or polymers

- Celebrated for their adaptability, flexibility, superior sealing capabilities, high-stress cushioning, remarkable memory retention, and overall environmental resilience

Why Adherex?

Adherex provides a comprehensive array of gasket options, catering to a broad spectrum of applications. Our offerings are diverse in terms of materials, durability, and protection and are customizable, ensuring that every client finds the perfect fit for their needs. Whether for general use or more demanding industrial applications, Adherex’s gaskets are engineered to provide exceptional seal tightness and performance.

What truly sets Adherex apart is its dedicated experts guiding customers through the selection process. This personalized assistance guarantees that each client receives a solution tailored to industrial sealing, cushioning, or even more demanding applications, underlining Adherex’s commitment to innovation, quality, and unparalleled customer service.

FAQs

What is the most critical factor when selecting a gasket?

Material, pressure, and temperature are crucial factors to consider. To choose the appropriate gasket for your specific application, you must clearly understand the conditions to which your production process is exposed.

What makes a good gasket material?

Gaskets must be flexible and have the appropriate properties for their specific application. Engine use cases must provide a leak-proof seal that is heat resistant. Electronics applications may need sound dampening and antistatic properties. In short, the best gasket material is the one that best suits the job.

What is the difference between a gasket and a seal?

The line between a gasket and a seal is not clearly defined, and the term is often used interchangeably. Gaskets are generally flat, two-dimensional shapes used to seal two flat surfaces. They are usually made by cutting or pressing flexible materials. On the other hand, seals are typically three-dimensional and tend to be molded or machined.

RELATED ARTICLE

An Introduction to Foam Packaging Material

Ensuring that a package arrives with its contents intact is critical for retailers and manufacturers of all types. This is especially true in the transportation industry, where fragile parts like glass must be moved between facilities for assembly. Medical and food suppliers also need antimicrobial and temperature control solutions.

Access to a Broader, More Comprehensive Line of Products

In-Stock, Ready-to-Ship.

Hand- and Machine-Rolled Adhesion Solutions.

Available in Multiple Widths, Lengths & Materials.

Customizable to Meet Exact Customer Specifications.

BOPP Carton Sealing Tapes

BOPP Carton Sealing Tapes

Available in multiple grades of acrylic adhesive, synthetic rubber hot melt, solvent natural rubbers and solvent acrylic adhesives. We’ll meet your application requirements from functional to performance-grade adhesive systems.

Paper Tapes

Paper Tapes

Multiple product grades are available from general purpose tapes to high-performance products. Sizes range from standard market sizes to customized sizes to meet application-specific requirements for splicing, clean removal, UV resistance and more.

Cloth, Duct, Film & Foam

Cloth, Duct, Film & Foam

Single- and double-sided tapes are available in a broad range of grades, colors and sizes on a variety of substrates and specially formulated pressure sensitive adhesives. Performance characteristics range from waterproofing to noise and heat reduction.

Stretch Film

Stretch Film

Strapping Tape

Strapping Tape

Our line of adhesive solutions offers tensile strengths between 70 and 500 pounds to meet each customer’s unique requirements. A broad range of applications include securing products during transfer, carton sealing, bundling, load unitizing, reinforcement and security.

Customized Solutions

Customized Solutions

A wide range of assemblies and kits – including Returnable Packaging and Customized Put-Ups – leverage our in-house die-cutting and converting technologies. We’ll create the durability and strength needed for multiple uses, Class A surface protection and more.

Printable & Printed Tapes

Printable & Printed Tapes

Discover how our BOPP acrylic and hot melt tapes are being used for both top-side, printable products, as well as undersurface/lock printed materials to build awareness for your brand, create pilfer-proof packaging and more.

sanstrap® Pallet Bands

sanstrap® Pallet Bands

Our industry-leading pallet banding solution secures the top layer of a pallet with materials that are both recyclable and durable. The product provides a proven, quick, and easy way to ensure stabilization for intra-plant movement. Its ease of use provides tremendous savings in both labor and time.

Highest Quality Flexographic Film Printing

Highest Quality Flexographic Film Printing

Our advanced eight-color flexographic film printing is available for films up to 41 inches wide. With one of the world’s most productive flexographic printing systems, we can reliably print on multiple substrates including stretch film, low- and high-density PE, BOPP and multilayered film composites. Integrated technologies ensure waste-minimizing set-ups, quick job changes, and automated print monitoring and inspection processes.