Adherex packaging | Protective Packaging

Foam Packaging

Foam Packaging

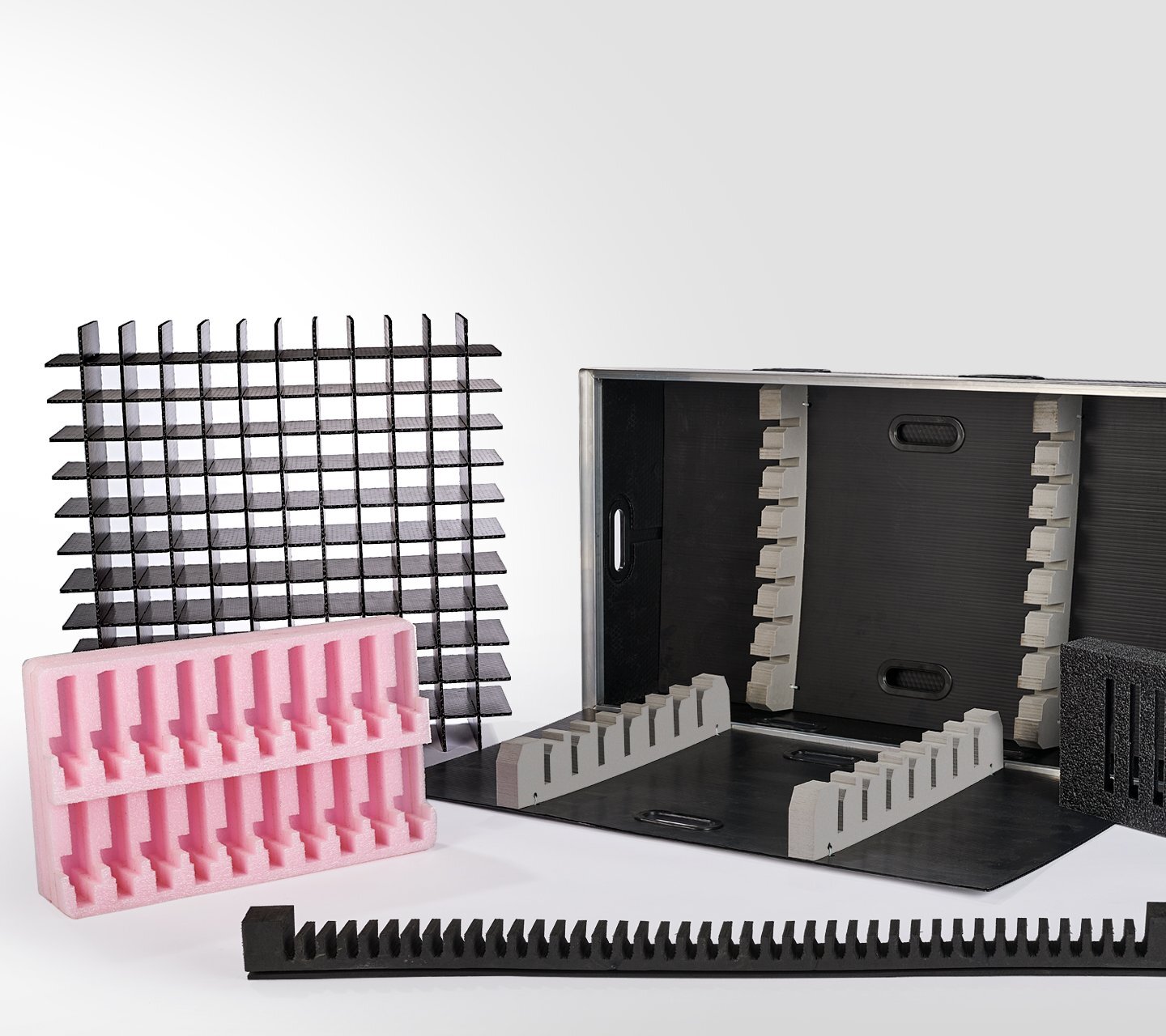

Adherex’s foam packaging is a wide-ranging collection of protective solutions constructed from plastic compounds that each have their own unique benefits. Foam packaging is available in sheets or rolls, pouches, and molded, die, or jet-cut 3D forms. Made from polyethylene, polypropylene, polystyrene, polyurethane, and other variants, foam can be used as general-purpose packing material or custom-designed as dunnage for one-of-a-kind products. In addition to cushioning, various foam types can also offer stretch, high friction coefficient (“stickiness”), insulation, compression, and scratch protection.

Foam Sheets/Rolls/Pouches

PE Stretch Foam (Polyethylene)

PU Foam (Polyurethane)

EPS Foam (Expanded Polystyrene)

PE Foam (Polyethylene)

EPE Foam (Expanded Polyethylene)

EPP Foam (Expanded Polypropylene)

Lightweight Protection

Paper, bubble wrap, and corrugated cardboard are useful shipping materials, but are limited in the amount of protection they can offer. Some objects are too delicate, too heavy, or have other special needs that can’t be accommodated with general use packaging. Foam packaging offers a simple but comprehensive alternative. Polyurethane foam can cushion heavy objects, guard against scratches, and compress or expand to fill a space. Expanded polystyrene is an excellent insulator and protects against crushing. Polyethylene foam takes many forms, and can be used in versatile sheets to wrap products, or in water jet cut custom shapes as protective dunnage. Adherex offers a wide variety of foam packaging types to meet any shipping challenge.

Foam Packaging Solutions for Any Application

Foam Sheets/Rolls/Pouches:

Layers of foam in varying thicknesses offer a versatile option for wrapping or interleaving between fragile items, lining containers, or—when used as pouches—organizing smaller products. These sheets are typically made from polyethylene, polypropylene, polyurethane, and occasionally polystyrene.

PE Stretch Foam (Polyethylene):

This tear-resistant foam fits uniquely shaped items and has a high coefficient of friction—it clings to the surfaces it protects without damaging them, and prevents sliding during shipping.

PU Foam (Polyurethane):

Polyurethane foam is soft and flexible, frequently used for upholstery or in “egg crate” cushioning. Adherex can craft die-cut specialty pieces for unique applications.

EPS Foam (Expanded Polystyrene):

EPS foam is rigid but protective, preventing delicate items from scratching or crushing. It is also an excellent insulator, and can line food or medical storage containers—or even be made into a container itself. It is extremely light, minimizing the impact to shipping costs.

PE Foam (Polyethylene):

Another rigid foam, PE foam is more durable and less brittle, making it ideal for holding items in place during transportation or minimizing vibrations. It can also be used to insulate items that need to be kept cool.

EPE Foam (Expanded Polyethylene):

This foam is extremely strong and compact, but also flexible. EPE foam can also provide insulation, and is more space-efficient than other foam options, although not as protective against scratching. For special applications or custom dunnage, Adherex offers die and water jet cutting.

EPP Foam (Expanded Polypropylene):

EPP foam is strong and handles compression well, making it a good option for transporting heavy or unsteady objects. It is also used as insulation in homes and cars. Because it is specially molded, it is most commonly used for highly specific applications.

Why Adherex?

Adherex’s wide range of foam packaging solutions gives manufacturers and distributors the flexibility to find exactly the right solution for their needs, whether they are searching for dunnage, insulation, or specialty shipping protection. Customers can consult with Adherex’s protective packaging experts on foam properties and applications, and specialty manufacturers can take advantage of Adherex’s die and water jet cutting capabilities—not offered by many vendors domestically—to design the perfect packaging solution. Adherex is invested in customers’ success, and in finding the foam packaging solution that fits their needs and budget.

FAQs

Should I choose PE or PU foam?

Polyurethane foam’s flexibility and insulating properties makes it well suited to furniture, upholstery, and certain automotive applications. Polyethylene foam absorbs shock well and resists moisture, making it popular for packaging, construction materials, and sports equipment.

Can PE and PU foams be recycled?

Yes—but they are not equally easy to recycle. Polyethylene foam can be melted and re-formed fairly easily, while polyurethane foam is more often repurposed as-is or chemically dissolved. Check with your local government or recycling program for more information and regulations.

Is PU foam toxic?

No, polyurethane foam is not toxic in itself. However, certain additives and production methods introduce chemicals that can have adverse effects on human health. To minimize any risk when working with PU foam, wear personal protective equipment and ensure adequate ventilation.

RELATED ARTICLE

An Introduction to Foam Packaging Material

Ensuring that a package arrives with its contents intact is critical for retailers and manufacturers of all types. This is especially true in the transportation industry, where fragile parts like glass must be moved between facilities for assembly. Medical and food suppliers also need antimicrobial and temperature control solutions.

Access to a Broader, More Comprehensive Line of Products

In-Stock, Ready-to-Ship.

Hand- and Machine-Rolled Adhesion Solutions.

Available in Multiple Widths, Lengths & Materials.

Customizable to Meet Exact Customer Specifications.

BOPP Carton Sealing Tapes

BOPP Carton Sealing Tapes

Available in multiple grades of acrylic adhesive, synthetic rubber hot melt, solvent natural rubbers and solvent acrylic adhesives. We’ll meet your application requirements from functional to performance-grade adhesive systems.

Paper Tapes

Paper Tapes

Multiple product grades are available from general purpose tapes to high-performance products. Sizes range from standard market sizes to customized sizes to meet application-specific requirements for splicing, clean removal, UV resistance and more.

Cloth, Duct, Film & Foam

Cloth, Duct, Film & Foam

Single- and double-sided tapes are available in a broad range of grades, colors and sizes on a variety of substrates and specially formulated pressure sensitive adhesives. Performance characteristics range from waterproofing to noise and heat reduction.

Stretch Film

Stretch Film

Strapping Tape

Strapping Tape

Our line of adhesive solutions offers tensile strengths between 70 and 500 pounds to meet each customer’s unique requirements. A broad range of applications include securing products during transfer, carton sealing, bundling, load unitizing, reinforcement and security.

Customized Solutions

Customized Solutions

A wide range of assemblies and kits – including Returnable Packaging and Customized Put-Ups – leverage our in-house die-cutting and converting technologies. We’ll create the durability and strength needed for multiple uses, Class A surface protection and more.

Printable & Printed Tapes

Printable & Printed Tapes

Discover how our BOPP acrylic and hot melt tapes are being used for both top-side, printable products, as well as undersurface/lock printed materials to build awareness for your brand, create pilfer-proof packaging and more.

sanstrap® Pallet Bands

sanstrap® Pallet Bands

Our industry-leading pallet banding solution secures the top layer of a pallet with materials that are both recyclable and durable. The product provides a proven, quick, and easy way to ensure stabilization for intra-plant movement. Its ease of use provides tremendous savings in both labor and time.

Highest Quality Flexographic Film Printing

Highest Quality Flexographic Film Printing

Our advanced eight-color flexographic film printing is available for films up to 41 inches wide. With one of the world’s most productive flexographic printing systems, we can reliably print on multiple substrates including stretch film, low- and high-density PE, BOPP and multilayered film composites. Integrated technologies ensure waste-minimizing set-ups, quick job changes, and automated print monitoring and inspection processes.