Adherex packaging | Protective packaging

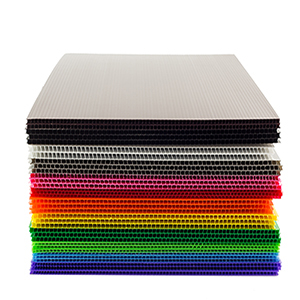

Corrugated Plastic

What is Corrugated Plastic?

Corrugated plastic sheets have a wavy inner layer for structural stability, like corrugated cardboard. Corrugated plastic is extruded, cutting lead time over traditionally molded plastic from six months to roughly four weeks. The extruded plastic sheets are cut and then assembled into totes or boxes for storing and carrying items, dividers to organize items inside boxes and totes, and custom die-cut sheets to protect specialty items. The durability of these containers makes them great for shipping, storage, and warehouse applications across industries. Additionally, the material is lightweight, lowering shipping costs, and easily customized for your organization’s specific needs.

Lightweight, Yet Durable

Staying organized deeply affects the bottom line of manufacturers and shippers. Color-coded corrugated plastic containers are an easy and affordable method of organization that can be customized to your existing system or considered when designing new warehouse systems. Traditional molded plastic sheets are often too brittle or easily damaged and cannot withstand the wear and tear of shipping. Totes and boxes made of this material are highly stackable, especially when reinforced with steel, helping you get the most out of your warehouse space. Corrugated inserts can also help create a protective lining for fragile products during shipping or storage. This type of container can last for years and is recyclable once its lifespan is over.

Affordable, Customizable Solutions

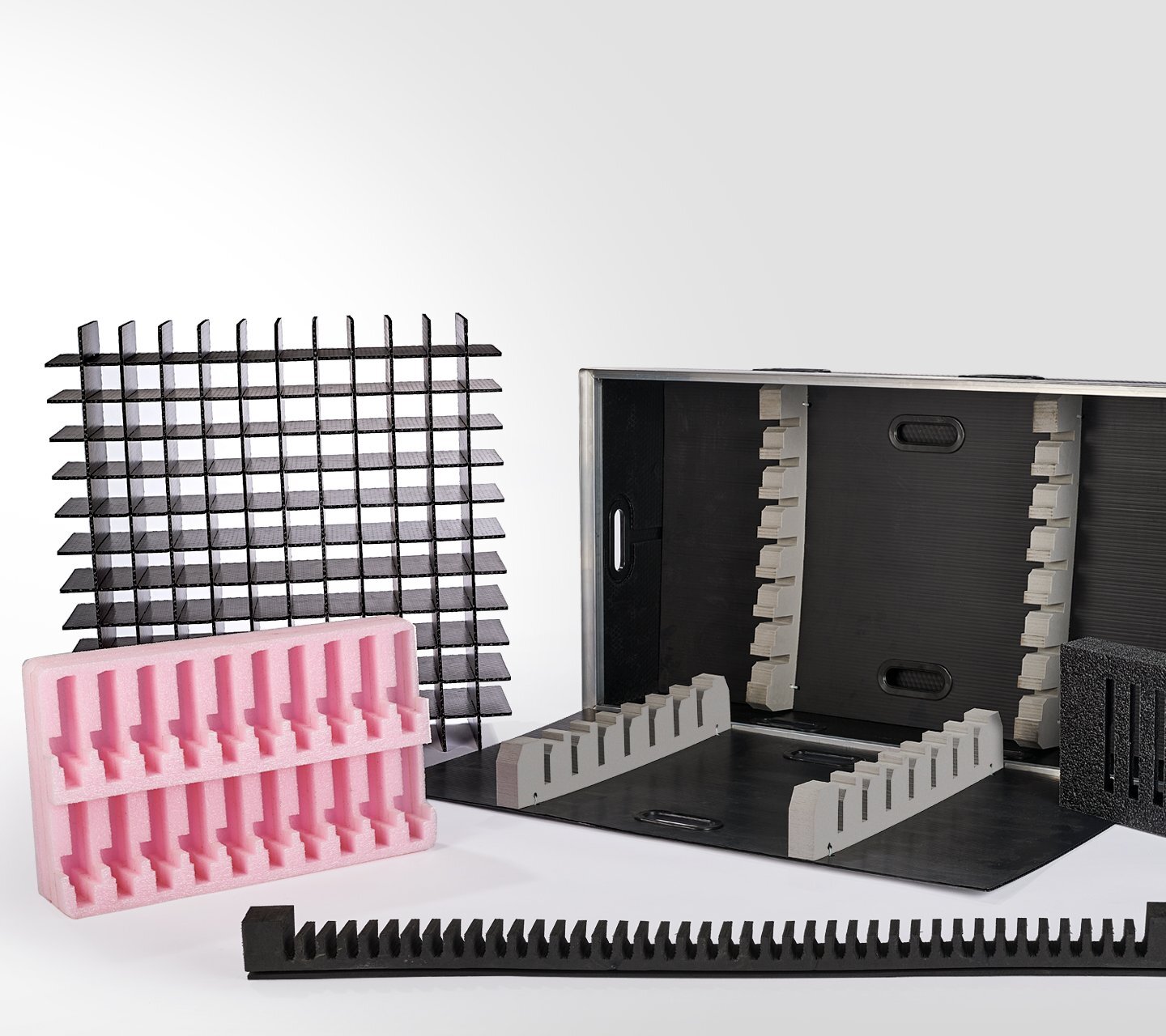

Corrugated Plastic Dividers/Partitions:

Dividers and partitions fit existing or customized totes and boxes.

- Sheets can be die-cut for specific containers and applications.

- Dividers are lightweight, flexible, and strong enough to keep items in place during transit.

Corrugated Plastic Boxes and Totes:

These lightweight totes are a favorite of the US postal system, preferred for their durability and lightweight.

- Totes and boxes of various sizes and colors can optimize supply chains and storage.

- Many of these boxes fold flat to maximize space when not in use.

- They are also more stackable than cardboard, stronger, and more flexible than molded plastic.

Die-Cut Corrugated Plastic:

Die-cut plastic allows protection and organization for unusually shaped and fragile objects.

- Multiple die-cut pieces can be assembled into one specific packaging solution or application.

- Rapidly prototype new packaging designs and test long-term solutions in your storage and conveyor systems.

Why Adherex?

Choosing suitable materials for shipping and storage containers is critical to achieving a cost-efficient supply chain. We start with your unique applications and advise you based on our decades of collective knowledge.

Adherex offers a variety of corrugated plastic products from a single source, catering to diverse manufacturing, storage, and shipping needs. Our corrugated plastic products can be assembled to create customized packaging for specific products. Adherex also provides a die-cutting service for plastic sheets, which is essential for solving supply chain issues and particular applications.

Our experts can identify the exact product your business needs or create a custom, purpose-built product that helps you manage inventory with precision.

FAQs

How durable is corrugated plastic?

Very durable. These containers are weather-, UV-, and chemical-resistant and can be enhanced with specialized treatments to extend shelf life. Additionally, some corrugated plastic boxes can be fortified with steel to increase strength further and improve stackability. You can expect this container category to last at least five years or longer in ideal conditions.

What are the advantages of corrugated plastic?

It is lightweight and has an incredibly high durability-to-weight ratio. Additionally, it is long-lasting, highly customizable, and affordable.

Is corrugated plastic UV-resistant?

Yes, and it gains further resistance when coated with additional UV treatment.

When should I avoid using corrugated plastic?

While very durable, corrugated plastic is not ideal for storing loads over 30 lbs (although this rating can be increased with steel reinforcement). In addition, an outdoor application may not be the right setting for this material, as prolonged exposure to the elements can lead to a shorter life span.

Is corrugated plastic recyclable?

Yes, it is recyclable at most major recycling centers.

RELATED ARTICLE

Warehouse supplies and customer service

“Green”, “carbon-neutral”, and “sustainable” are all buzzwords drifting around the packaging industry. While implementing “green” packaging is a worthy goal, the reality behind sustainable packaging materials is complicated. To begin with, there is much confusion regarding sustainability in the packaging supply chain. Currently, popular marketing labels like “eco-friendly” and “sustainability” don’t have a firm definition.

Access to a Broader, More Comprehensive Line of Products

In-Stock, Ready-to-Ship.

Hand- and Machine-Rolled Adhesion Solutions.

Available in Multiple Widths, Lengths & Materials.

Customizable to Meet Exact Customer Specifications.

BOPP Carton Sealing Tapes

BOPP Carton Sealing Tapes

Available in multiple grades of acrylic adhesive, synthetic rubber hot melt, solvent natural rubbers and solvent acrylic adhesives. We’ll meet your application requirements from functional to performance-grade adhesive systems.

Paper Tapes

Paper Tapes

Multiple product grades are available from general purpose tapes to high-performance products. Sizes range from standard market sizes to customized sizes to meet application-specific requirements for splicing, clean removal, UV resistance and more.

Cloth, Duct, Film & Foam

Cloth, Duct, Film & Foam

Single- and double-sided tapes are available in a broad range of grades, colors and sizes on a variety of substrates and specially formulated pressure sensitive adhesives. Performance characteristics range from waterproofing to noise and heat reduction.

Stretch Film

Stretch Film

Strapping Tape

Strapping Tape

Our line of adhesive solutions offers tensile strengths between 70 and 500 pounds to meet each customer’s unique requirements. A broad range of applications include securing products during transfer, carton sealing, bundling, load unitizing, reinforcement and security.

Customized Solutions

Customized Solutions

A wide range of assemblies and kits – including Returnable Packaging and Customized Put-Ups – leverage our in-house die-cutting and converting technologies. We’ll create the durability and strength needed for multiple uses, Class A surface protection and more.

Printable & Printed Tapes

Printable & Printed Tapes

Discover how our BOPP acrylic and hot melt tapes are being used for both top-side, printable products, as well as undersurface/lock printed materials to build awareness for your brand, create pilfer-proof packaging and more.

sanstrap® Pallet Bands

sanstrap® Pallet Bands

Our industry-leading pallet banding solution secures the top layer of a pallet with materials that are both recyclable and durable. The product provides a proven, quick, and easy way to ensure stabilization for intra-plant movement. Its ease of use provides tremendous savings in both labor and time.

Highest Quality Flexographic Film Printing

Highest Quality Flexographic Film Printing

Our advanced eight-color flexographic film printing is available for films up to 41 inches wide. With one of the world’s most productive flexographic printing systems, we can reliably print on multiple substrates including stretch film, low- and high-density PE, BOPP and multilayered film composites. Integrated technologies ensure waste-minimizing set-ups, quick job changes, and automated print monitoring and inspection processes.