What is flexographic printing?

Flexographic printing (flexography or flexo) is a technology with roots in the printing press. It takes the same concept—a relief plate covered with ink pressed to a printing surface—and applies it to a series of high-speed cylinders. Flexo can be used on a wide variety of substrates (printing surfaces), including cardboard, paper, and different plastic films. This post will review the types of flexographic printing inks available for different kinds of products and the pros and cons of each.

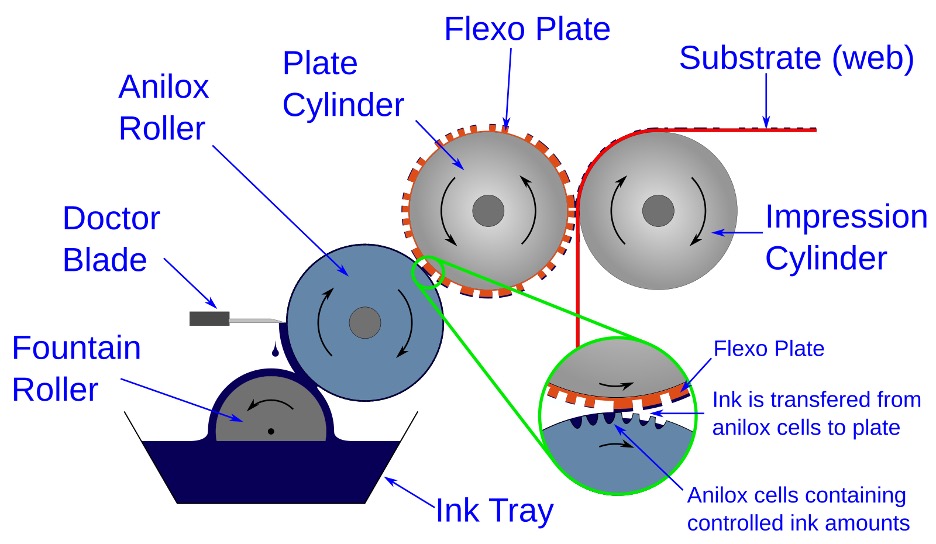

How flexography works

To fully understand and choose the correct ink for your products, you need a general understanding of how flexography works.

Flexography operates through a system with a metering roller (aka fountain roller) submerged in ink, which transfers ink to an anilox roller. The anilox roller is precisely engraved with fine, honeycomb-shaped cavities that hold the ink. The design and size of these cavities directly influence the volume of ink applied; smaller and finer pockets result in a reduced ink transfer. The “doctor blade” also scrapes off excess ink back into the ink tray. This mechanism allows for precise control over ink application onto the flexo plate , ensuring high-quality printing results.

Each color of a print run must go through similar connected apparatuses. The process requires precision in preparing and aligning the plates. Because of the press’s high speed, the smallest mistake can ruin hundreds of products.

Learn more: Offering Speed, Versatility, and Quality with Flexographic Printing

Applications of flexographic printing

Flexography offers distinct advantages over lithography, particularly the ability to utilize a broader spectrum of inks, including water-based inks, instead of traditional oil-based options.

Flexo is suitable for a diverse array of substrates:

- Paper

- Plastic containers, tape, and film, including polyolefins, polypropylenes, polyethylenes, and PET

- Foil

- Kraft paper and cardboard

- Paper packaging tape

Products produced by flexographic printing include:

- Flexible packaging, such as retail and shopping bags

- Food-safe packaging, including bags, sleeves, and pouches

- Self-adhesive labels

- Disposable dishware and containers

- Wallpaper

The industry has recently witnessed an increasing trend towards using laminates, where two or more materials are bonded together. This innovative approach enhances the properties of the resulting composite material, offering unique benefits that neither of the original materials possessed.

Also read: Packing Industry Trends to Watch in 2025

Types of ink

There are three types of ink commonly used in modern flexographic printing:

- Solvent-based ink: Used primarily on plastic films

- Water-based ink: Used primarily on paper-based packaging and products that must be food-safe or with sustainability concerns

- UV-cured ink: Used mainly in narrow-web printing, Labels, and on unusual substrates such as glass

Pros and cons of different flexographic printing ink

Adherex does not currently have UV-cured printing capabilities, so we will focus on the differences between water- and solvent-based inks in the chart below. However, it’s important to mention that UV inks generally cost significantly more than other types. Additionally, they contain volatile organic compounds (VOCs), which are not well-suited for food applications.

| Ink Type | Advantages | Drawbacks |

| Solvent-based |

|

|

| Water-based |

|

|

Adherex capabilities

Through Adherex Group member Stretchtape, Adherex has comprehensive flexographic printing capabilities:

- 8-color press for enhanced visual impact and color vibrancy

- Able to print on a diverse array of substrates, including both rigid and flexible materials, with the capability to handle ultra-thin films that have thicknesses as low as 0.6 mm

- Offers flexibility with both solvent-based and water-based inks to meet diverse printing requirements

- Printing speeds of up to 1,500 feet per minute maximize efficiency for large and small print runs

- Automated registration capabilities ensure high image accuracy within tight tolerances

- An intelligent vision system that detects dirt, debris, and print defects, maintaining print quality and minimizing waste

- Proprietary equipment to drive the solvents out of the ink, which we then use to fire our ovens, allowing us to run much cleaner

- Self-cleaning press with much faster job changeovers, reducing changeover time from two hours to twenty minutes

The speed of our print jobs enables us to take on smaller runs than are generally feasible for industrial-scale flexographic printers, making this technology accessible even to small businesses.

Additionally, we are preparing our printing facility to meet GMP and SQF compliance for producing food-safe packaging. Stay tuned for more updates as we enhance our capabilities in this critical market.

Adherex: Over 100 years of combined printing experience

With a team boasting over a century of combined flexographic printing experience, we are here to ensure you match the correct ink (and materials) to the right products. Our experts collaborate across various disciplines, allowing us to tailor our offerings to meet your packaging needs.

No matter the sector—food, health, personal care, and more—we understand the intricacies of your industry. Our knowledgeable customer service team is ready to assist you in selecting the ideal packaging solutions that align with your budget, sustainability goals, and operational demands.

Don’t settle for generic packaging. Let us help you create something exceptional. Contact Adherex today to discover how we can support your business with our innovative and customizable packaging options.